China remains the world’s leading exporter of apparel, serving thousands of global fashion brands. However, as production scales, so do the risks of quality issues, inconsistent workmanship, and missed deadlines. To mitigate these challenges, international buyers increasingly rely on product inspection in China — especially for garment quality control.

By collaborating with experienced third-party inspection agencies, buyers can ensure that every shipment meets their exact specifications before it leaves the factory.

Contents

Why Product Inspection in China Matters

Manufacturing garments in China offers many advantages, including cost-efficiency and flexible production capabilities. But without proper quality control, even the best designs can be compromised by:

- Incorrect sizing or labeling

- Defects in stitching or fabric

- Poor finishing or packaging

- Color variation and fading

That’s why product inspection in China is critical. It ensures your products are manufactured to your standards and helps you avoid costly delays, customer complaints, and returns.

Key Elements of Garment Quality Control

Effective garment quality control involves a detailed evaluation of both visual and functional aspects of clothing. A qualified third-party inspection team will check:

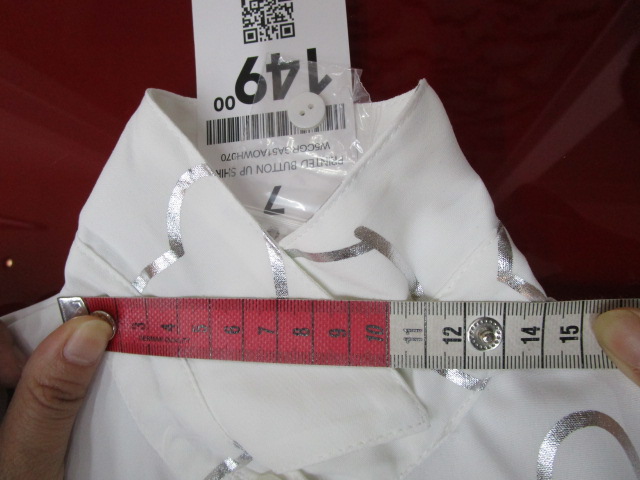

- Measurements and fit: Comparing actual sizes to tech pack or order specs

- Stitching and construction: Seam strength, alignment, density, and defects

- Fabric quality: Texture, color consistency, weight, shrinkage, and elasticity

- Trims and accessories: Zippers, buttons, snaps, labels, hangtags

- Workmanship: Loose threads, stains, unfinished edges, symmetry

- Packing and labeling: Barcode accuracy, polybag sealing, carton drop testing

Inspections are usually performed based on AQL (Acceptable Quality Limits), with defect classification into critical, major, and minor categories. This ensures an objective and standardized approach.

How to Work with a Third-Party Inspection Company

Partnering with a third-party inspection agency in China gives you independent, unbiased reports about your product’s quality before shipment. The process typically includes:

- Booking the inspection at least 1-2 days before shipment

- Inspector visits the factory to conduct on-site inspection

- Comprehensive report issued within 24 hours with photos, findings, and recommendations

- Approval or rework based on inspection results

This process helps buyers make informed decisions while saving time and reducing risk — especially if you are managing multiple suppliers in different regions of China.

Why Choose NBNQC?

NBNQC is a leading third-party quality control and inspection company in China, trusted by importers across Europe, North America, and Australia. Our team has in-depth experience in garment quality control, helping fashion brands and retailers maintain consistent quality and compliance.

Why NBNQC?

- Fast on-site inspections — results within 24–36 hours

- Detailed, easy-to-read reports with photos and measurements

- Customizable checklists tailored to your product and brand

- Local inspectors across key garment production areas (Guangdong, Zhejiang, Jiangsu, Fujian, etc.)

- Transparent pricing and efficient communication in English and Chinese

With NBNQC, you get more than just inspection — you gain a reliable partner to help you grow your business with confidence.

Conclusion

When sourcing garments from China, ensuring product quality is non-negotiable. A dependable product inspection in China service gives you peace of mind, reduces the chance of defects, and protects your brand image.

For precise, professional, and efficient garment quality control, NBNQC stands out as one of the most trusted third-party providers in the Chinese inspection industry.